Free PCB design software can be a great thing, especially when you’re just getting started as a new designer or a hobbyist. As you gain more experience and you start working with more complex products or in a professional setting you’ll start to find that each KiCad and Altium Designer software tools have nuances, but there is only one that focuses on productivity for professional hardware. Select plot after clicking the file, to open the plot window. 64: Screenshot of Plot Button in File Menu in KIcad. Do the things in the plot window as shown in the following figure: Fig. 65: Screenshot of Plot Window in KIcad. Now go to the main window and click the “gerbview” button to open. How to export Kicad PCB to gerber files Generate Drill and Gerber Files. Select File - Plot from the menu to open the gerber generation tool. In general, there are 8x layers you need to have a PCB fabricated: Top Copper (F.Cu)+ Soldermask (F.Mask) + Silkscreen (F.SilkS) Bottom Copper (B.Cu) + Soldermask (B.Mask) + Silkscreen (B.SilkS). Carbide Copper will open Gerber RS247X format files and Excellon drill files. Every program outputs a slightly different version of the file so it’s conceivable that it will not work with all PCB software. We’ve tested it with Eagle extensively and are committed to making it work with all popular PCB software. Can I add my own cutters? How to export Kicad PCB to gerber files KiCad is an open-source software tool for the creation of electronic schematic diagrams and PCB artwork. Beneath its singular surface, KiCad can be considered mature enough to be used for the successful development and maintenance of.

Carbide Copper is CAM software to let you mill PCBs with your CNC machine.

Carbide Copper is the fastest way to make same-day circuit boards in your own office or shop

Save Time

With Carbide Copper and your CNC machine, you'll be able to go from design to prototype PCB's within the hour.Save Money

By creating your PCB with Carbide Copper, you'll pay only the material costs for the boards you make.No minimum order quantities, no shipping charges.

Iterate faster

Being able to create a new board revision (or more) each day, how much faster can you complete you projects?Free to use

Carbide Create is free to use for everyone. We made it for our Nomad Pro CNC machine, but we welcome owners of other CNC machines to use it as well.Feel free to use Carbide Copper if you already have a CNC machine. If not, check out the Nomad.

Frequently Asked Questions

Is it free?

Carbide Copper is free to use for everyone. Of course, we make it available primarily for our users, we welcome everyone to use it.

Will it remain free?

We have no plans to close it up to only Carbide 3D customers. We absolutely want it to be free to use for the long term.

Will it work with my machine?

Carbide Copper outputs very basic gcode so it should work with almost any CNC machine that uses gcode.

What PCB software will it work with?

Carbide Copper will open Gerber RS247X format files and Excellon drill files. Every program outputs a slightly different version of the file so it’s conceivable that it will not work with all PCB software.

We’ve tested it with Eagle extensively and are committed to making it work with all popular PCB software.

Can I add my own cutters?

Open Kicad_pcb File Online File

A custom tool library is on the TODO list for a future release. We think that will add a ton of value but it’s not something we were able to get done at launch.

Can I run it offline?

Carbide Copper is a cloud app that runs from our website. We will make a downloadable version available in the future for owners of Carbide 3D machines.

Can you add support for my machine?

The gcode from Carbide Copper is very basic but it some machines may need additional codes add or some lines removed. We may add a way to do this in future releases but that’s not available in the first release.

Is support available?

Support is available for Carbide 3D customers via email and phone, or in our forum.

Will it do two-sided PCB’s?

We will offer a “real” two-side workflow in a future release.

Is it open source?

Carbide Copper is free to use but is not open source.

What platform does it run on?

Carbide Copper is a cloud-based app that run on any machine with a modern browser, including OS/X, Windows, and Linux.

Usually, it is easier to generate Gerber files using Kicad than other PCB design software. All you need to do is to select the necessary layers and to not forget generating the DRILL file. Now, let’s get started!

1. Open your .kicad_pcb file

After opening your Kicad project - .pro file, you can double click the .kicad_pcb file or click the “PCBNew” button to open your PCB editor.

2. Plot your Kicad PCB as Gerber files

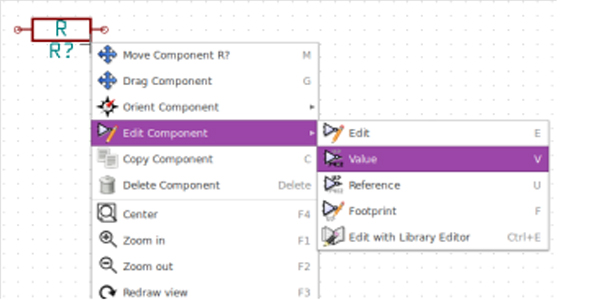

Click the “File” menu -->”Plot” and choose the necessary layers shown as below (for 2 layer boards), then click the “Plot” button to generate the related layers.

The necessary layers for 2-layer PCB could be:

Top Layer: pcbname.GTL

Kicad Pcb

Bottom Layer: pcbname.GBL

Solder Mask Top: pcbname.GTS

Solder Mask Bottom: pcbname.GBS

Silk Top: pcbname.GTO

Silk Bottom: pcbname.GBO

Drill Drawing: pcbname.TXT

Board Outline:pcbname.GML/GKO

Kicad Pcb Software

Note: In order to facilitate our access to your files, please do NOT check the 'Include extended attributes' before Plot.

3. Generate the drill file

Before closing the plot window, you need also generate the drill for manufacturing. Select “Suppress leading zeros” and “Minimal header” and click “Drill File” button as following shown.

4. Check the Gerber files in GerbView

Now you have finished the job. But you should always check whether your Gerber files are working or not. Open the “GerbView” and check what your board looks like before sending it to manufacturer.

Now you can see your board like this.

5.Compress all the files in a single .zip file

The final step is to Compress all the files in a single .zip file, then you can fill out the form about your PCB parameters ( size, quantity , layers , thickness , etc ) on our “PCB Instant quote” page and upload your .zip ( Gerber ) file to PCBWay online system, our engineers will check it again and feedback to you if any problems happen before it can be fabricated. Here we go!